Aft Section

Building the fin can is based on my experiences building level 2 rockets and there are a few bits and pieces I want to add to make the rocket a bit more robust in this one area.

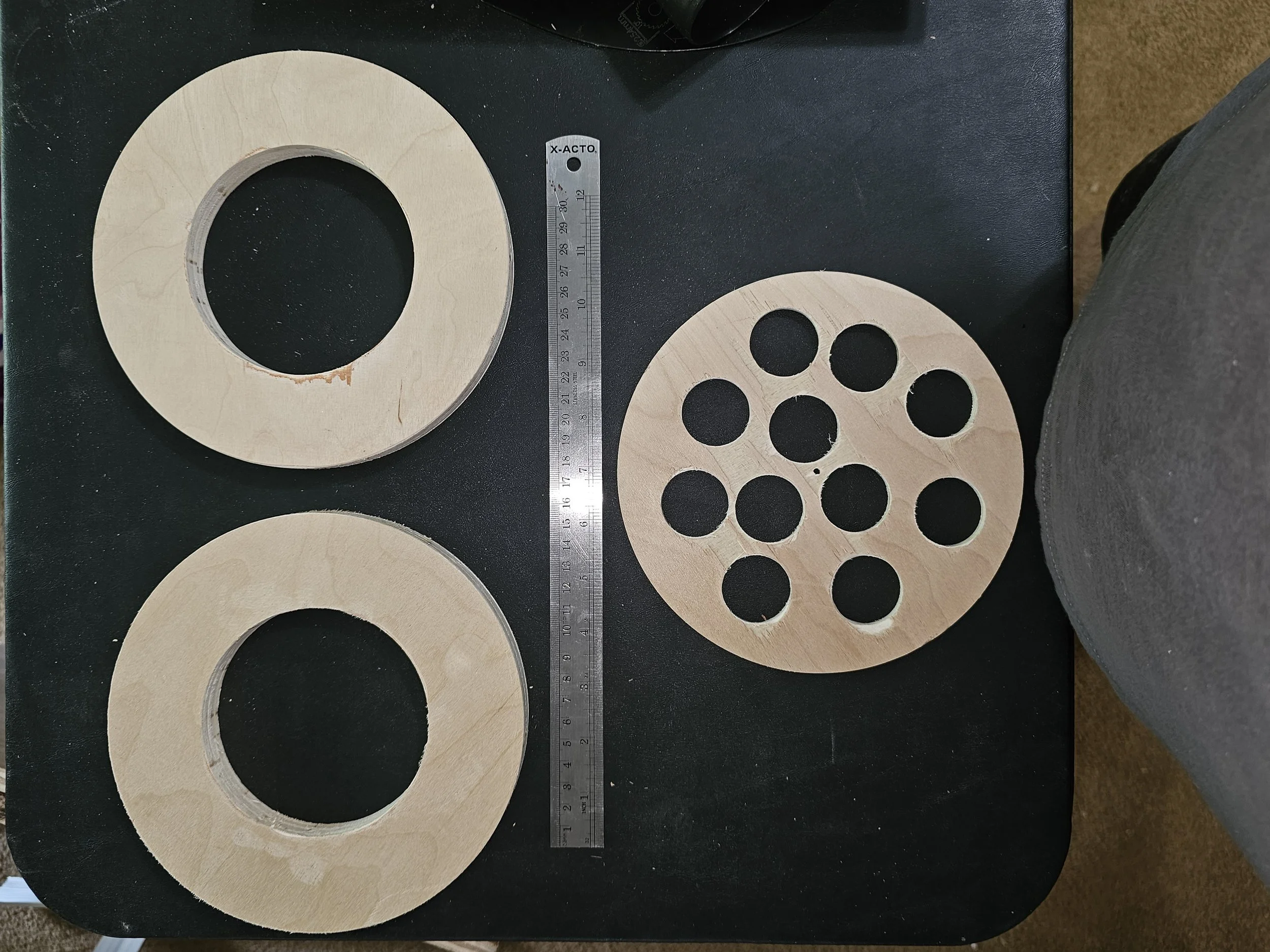

I am adding a 3/4” centering ring on top of the mid CR and after the aft CR. This will be for stronger mounting of the brass inserts for the 1515 rail buttons (left).

To the right is a chute shelf for the main chute. It protects the main chute from resting directly on the charge wells w/o impairing the pressurization of the payload tube to eject the chute.

I have been using Total Boat epoxies for my L2 build and all of the 3”+ rockets. I will be using this to laminate the body tubes with fiberglass (mid-tube and above) and carbon fiber (aft tube and fins).

I am using Total Boat’s THIXO for the external fin fillets as it should be a lot less runny.

There will be three (3) 1515 Delrin rail buttons (from rail-buttons.com). These will be mounted in the aft CR and mid CR.

The forward railbutton will be placed and in the upper coupler just above the AV bay, but beneath the chute shelf.

The buttons will be black to match the color scheme of the rocket.

I have been impressed with Soller Composites fiberglass sleeves for other rockets. I will use both their carbon fiber biaxial sleeve for the aft tube section and their fiberglass sleeve for the mid and payload tubes. Each has a thickness of .010 and should align well after lamination.

I am also using 3k biaxial CF twill on the fins. I am still thinking about a simple layup for tip-to-tip for fin strength.

The fin fin tube will be bolted to the mid-tube section for easy transport using eight (8) 1/4” x 20 T-nuts with hex head machine bolts. The bolts will be counter sunk into the airframe for a flush fit.

I have been using Aeropack motor retainers for all of my rockets with a 38mm MMT and larger.

I opted for the 98mm retainer in case I ever wanted to load up a 98mm motor.